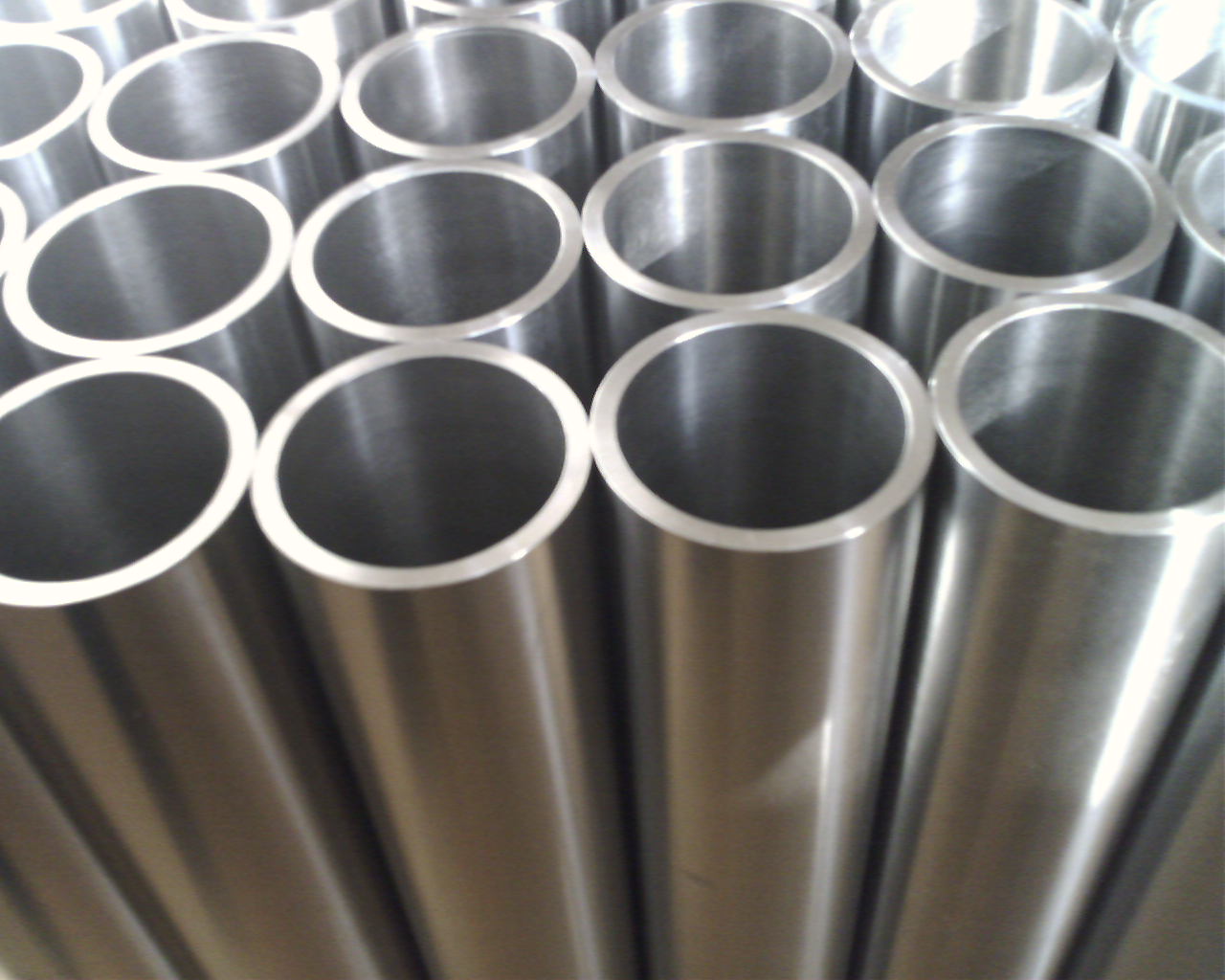

Bearing Steel

Bearing Steel

Rolling bearing steel is used in the manufacture of ball, roller and steel sleeve, etc., can also be used for the production of precision measuring tools, Die, machine screw and diesel pump precision coupling.

Overview

Bearing steel is used to make balls, rollers and bearing rings of steel. Bearing in work is under immense pressure and friction, it requires a high and uniform bearing steel hardness and wear resistance, and high elastic limit. The chemical composition of bearing steel uniformity, content and distribution of non-metallic inclusions, carbide distribution and other requirements are very strict, also known as high carbon bearing steel Ge steel, carbon Wc about 1 percent, including the amount of Ge is Wcr 0.5% -1.65%. Ge is divided into high-carbon bearing steel bearing steel, non-Ge bearing steel, carburizing bearing steel, stainless steel bearings, high temperature bearing steel and bearing steel shielded six categories.

Chemical Composition

GB, the rule of standard, Japanese standard chemical composition of the main steel tablePhysical Properties

The physical properties of bearing steel mainly to check the microstructure, decarburization, non-metallic inclusions, mainly low magnification. Generally are hot-rolled annealing, cold drawn annealed delivery. Delivery status should be specified in the contract. Steel low magnification must be free of shrinkage, subcutaneous bubbles, white point and microscopic pores. Center porosity, generally can not be more than 1.5 osteoporosis, segregation may not be more than two. Annealing organization should be fine-grained steel pearlite evenly distributed. Decarburization depth, non-metallic inclusions and carbide of shall comply with the relevant national standards.

Packaging

Diameter less than 20mm to package delivery, greater than 20mm can bare delivery. Should be coated with anti-rust cold drawn steel for oil. Quality assurance should be attached, indicating the steel, furnace number, weight, size, chemical composition, inspection standards and test results before the goods leave the factory.

Manufacturing Methods

Quality bearing steel smelting demanding, and requires strict control of sulfur and phosphorus content and distribution, and non-metallic inclusions, because the content and distribution of non-metallic inclusions affect the bearing life of a great steel. The higher the amount of inclusions, the shorter the life. In order to improve the quality of smelting, smelting furnace and has recently been adopted by the ESR, you can use a vacuum smelting, vacuum consumable refining new technology to improve the quality bearing steel.

Uses

In addition to doing ball bearing rings endures, sometimes used to make tools, such as dies, gauges, taps and so on.

Shandong AOBO Bearing Co., Ltd

Professionally customized bearings perfectly solutions for customers. AOBO is one of the leading bearing manufacturers in China. With 20 years’ experience, advanced manufacturing facilities and excellent management staff, we can produce products that are equivalent to the world leading brand bearings. We have our own bearing brand AOBO and also distribute bearings of global brands.

Contact Us:

Mr. Shawn

Mobile: +86-18766165306

Email: aobobearing@aobobearings.com

Skype: live:aobobearing

Wechat: aobobearing

Tel: +86-0531-88785536

Fax: +86-0531-88785636

Website: http://www.aobobearings.com

- Deep groove ball bearing

- Self-aligning ball bearing

- Cylindrical roller bearing

- Spherical Roller Bearings

- Angular contact ball bearing

- Tapered roller bearing

- Thrust ball bearing

- Thrust roller bearing

- Knuckle Bearing

- Needle Roller Bearing

- Spherical Surface Ball Bearing

- Automobile bearing

- Famous Brand Bearings